- Home

-

Products

-

Mobile Monitoring System for High-Risk and Special Work

Explosion-proof | Remote Monitoring | Gas Detection

Area Networking | One-click Alarm

-

Digital Mobile Gas Monitor

Explosion-proof | Gas Detection | Four-channel Probes

Audio-visual Alarm

-

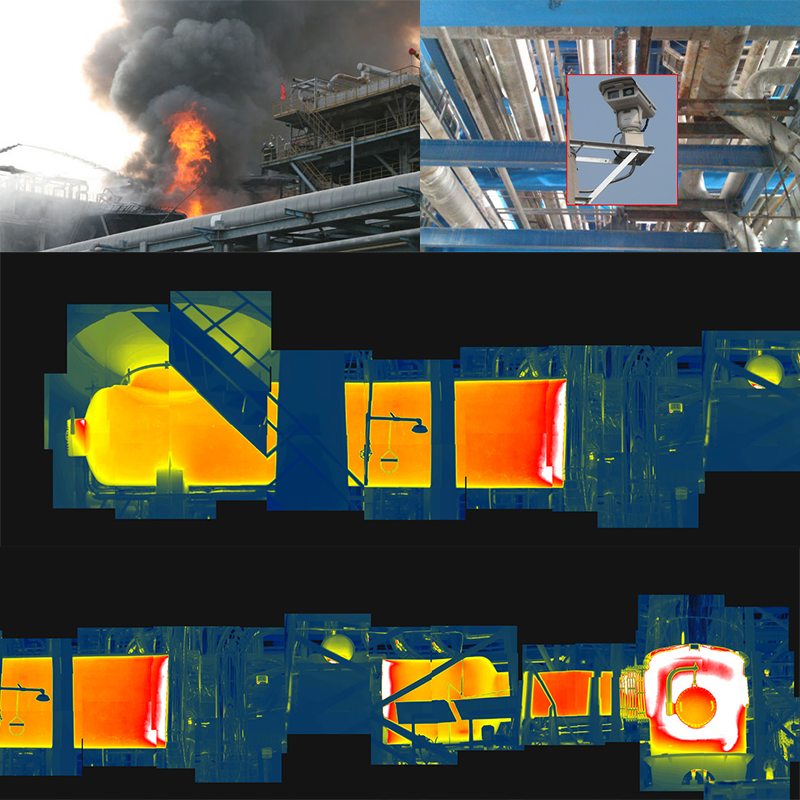

Visible Light+Infrared+Ai Intelligent Monitoring System

Explosion-proof Certification | Temperature Monitoring | Automatic Warning

Behavior Monitoring | Rich Interfaces | Wide Application

-

Intelligent Terminal (Universal Model)

Intrinsic Safety Explosion-proof | Dual Positioning | Fingerprint Recognition

Face Recognition | Custom Extension

Face Recognition | Custom Extension

-

High-Precision Positioning Intelligent Terminal

Intrinsic Safety Explosion-proof | Centimeter-level Positioning | Fingerprint Recognition

Face Recognition | Custom Extension

Face Recognition | Custom Extension

-

Warehouse Management Intelligent Terminal

Built-in RFID | Laser Scanning | Fingerprint Recognition

Face Recognition | Custom Extension

Face Recognition | Custom Extension

-

Infrared Thermal Imaging Intelligent Terminal

Infrared Thermal Imaging | Built-in RFID | Fingerprint Recognition

Face Recognition | Custom Extension

Face Recognition | Custom Extension

-

Industrial Data Acquisition Security Gateway

Massive Device Support | Multiple Data Services

Offline Cache Service | Automatic Alarm Service

Remote Management Service

-

-

Solutions

- Customer Case

- News Updates

- About Us

Infrared detector type:

Infrared detector type: